Why you need Specright

Why market leaders are adopting a spec-first approach

When everyone has access to specifications, amazing things happen – faster product development, improved quality, and less waste.

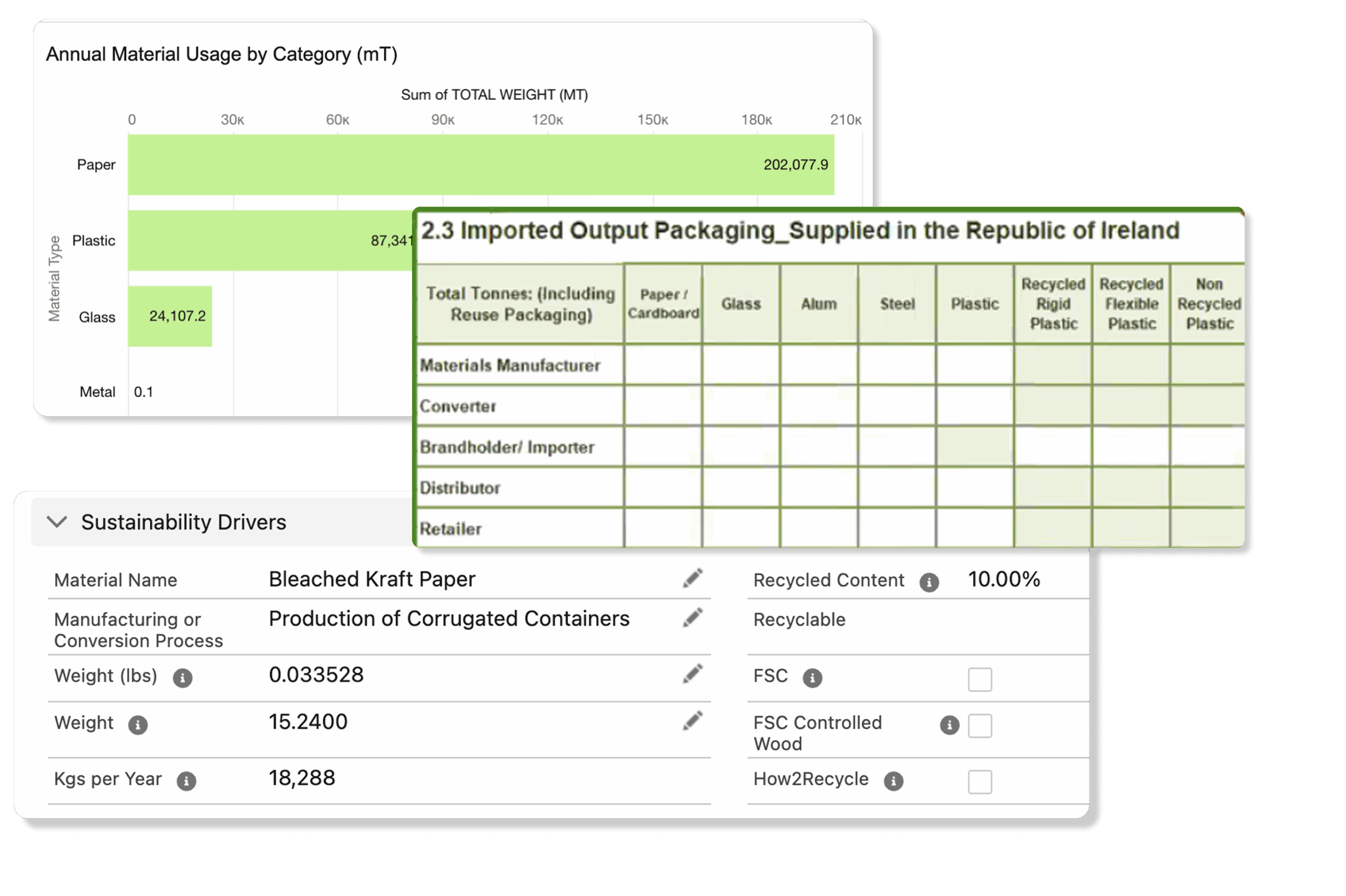

Centralizing spec data for enhanced accuracy and collaboration

“We decided to get Specright so that we could have a centralized location where we could have all of our packaging specifications. If we look up a pack code, it provides all of the information. It’s more of an automated system vs. manual.”

Gabriela Sanchez

Buyer-Material Control, Denso

Impact Metrics

10%

Faster New Product Development

30 – 40%

Increased Visibility into Sustainability Metrics

10%

+

Higher Supplier Compliance

25%

+

Reduced Risk of Recalls

Break down organizational silos with a single source of truth

Everyone needs access to the right specification data. While today many different teams own different parts of the specification, Specright has a solution.

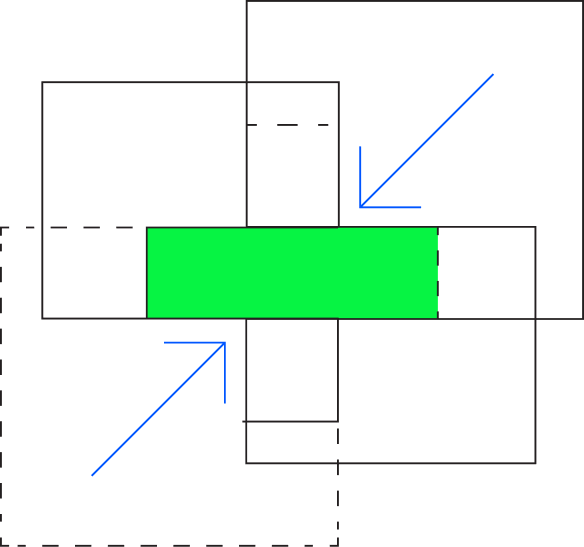

- Easily search at the component level

- Create better reports

- Collaborate with suppliers

- Develop new products faster

- Easily rationalize packaging SKUs

- Go to bid faster

- Automate quality checks

Streamline efficiency and collaboration across your teams and suppliers

“Specright has some of the open interfaces where they can tie into some of the other platforms that we use so it is not a full blown switchover. As long as Specright can be the source of truth for a lot of our information, and ommunicate with the other systems, then we can continue to operate efficiently.”

Frank Ardite

Global Quality & Digitization Director, BASF

Trusted by Fortune 500, private label retail & challenger brands

How customers are harnessing

the power of spec-first approach

At Specright, we tell our customers, “If you get the spec right, the rest follows.” But it resonates louder when coming from those who have seen the benefits of Specright firsthand. Hear our customers speak about the value they’re gaining from a spec-first approach.

“Specright saves our team a tremendous amount of time while increasing visibility and transparency across our supplier relationships so we can focus on preventing issues. Having the Spec Compliance Dashboards allows quality managers to have near real-time monitoring capabilities and spot hotline call trends. The confidence in our compliance program has increased since we started to use it.”

Jeff Chen

Quality Systems Manager, Jack in the Box

“Today, Specright serves as the primary source of truth for COOLA, breaking down data silos for good. As a lean organization, we have limited technology resources. It was critical we partner with a vendor that could be implemented without IT support. Specright delivered that and more.”

Michael Rentz

Senior Procurement Manager, COOLA

“Specright is a huge time and sanity saver. We now have one version of the truth that is far more reliable than the old way of doing things. It outperformed all the other systems we considered because it provided complete transparency down to the individual component level.”

Andrew Kesler

Corporate Director of Supplier Food Safety & Compliance Systems, Taylor Farms

If you get the spec right,

the rest follows

With digitized, shareable specs, you can ensure your teams and suppliers are on the same page– at all times.

2025 State of Specification Management Report

Companies are managing more complex specification data than ever—but outdated systems are holding them back. Our 2025 report reveals the top challenges facing packaging and supply chain teams today, from poor data accuracy and version control to mounting sustainability regulations.

Learn why 75% of respondents say they need better Specification Management, and how leading teams are transforming data chaos into competitive advantage.

Discover the Impact of Specification Management

Access our free resource library, and learn how to focus your data strategy, innovate, and drive your bottom line growth from industry experts.