Monthly Live Demo:

AI-Powered Insights and Actions

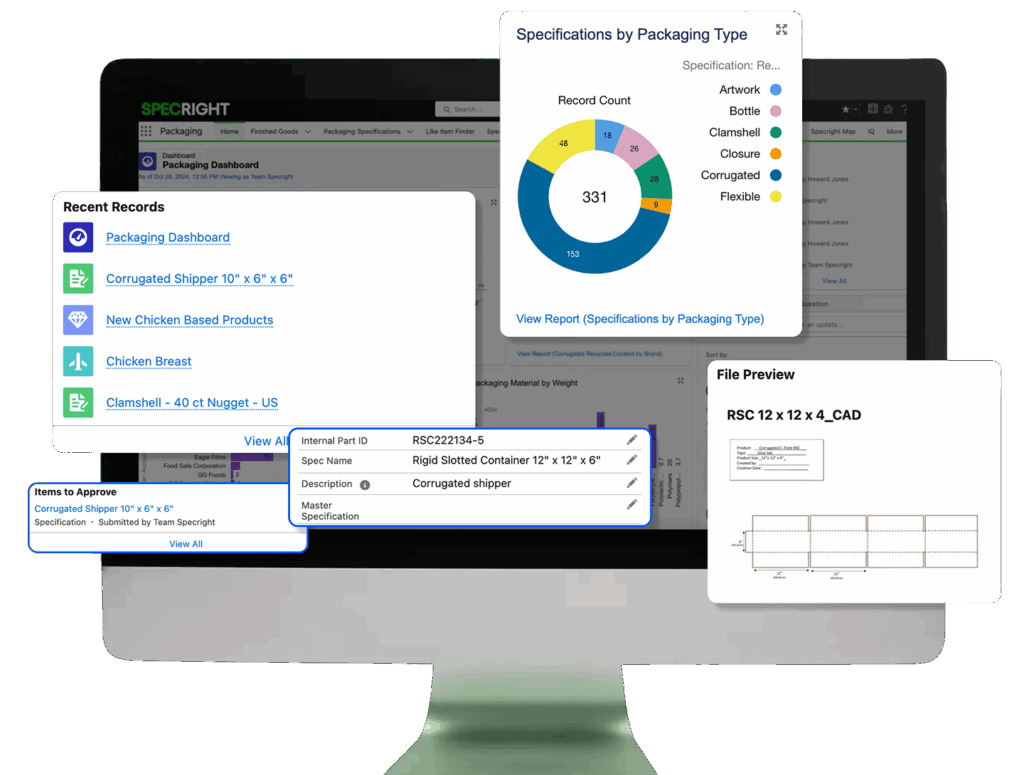

The #1 Platform for Product & Packaging Specification Management

Centralize your spec data to streamline development, ensure traceability, and stay ahead of regulatory demands with AI-powered insights.

Trusted by Fortune 500, private label retail & challenger brands

Your Products & Packaging Are Only as Good as Your Specs

Complete Product Transparency

Gain full visibility into what every product is made of, from individual components to complete ingredient lists.

Supply Chain Traceability

Track materials and ingredients back to their original sources for better risk management and compliance.

Proactive Material Management

Swap out materials or ingredients before issues arise, enabling preventive rather than reactive decision-making.

Enhanced Decision-Making Speed

Make faster, more informed decisions backed by comprehensive specification data for both current operations and future planning.

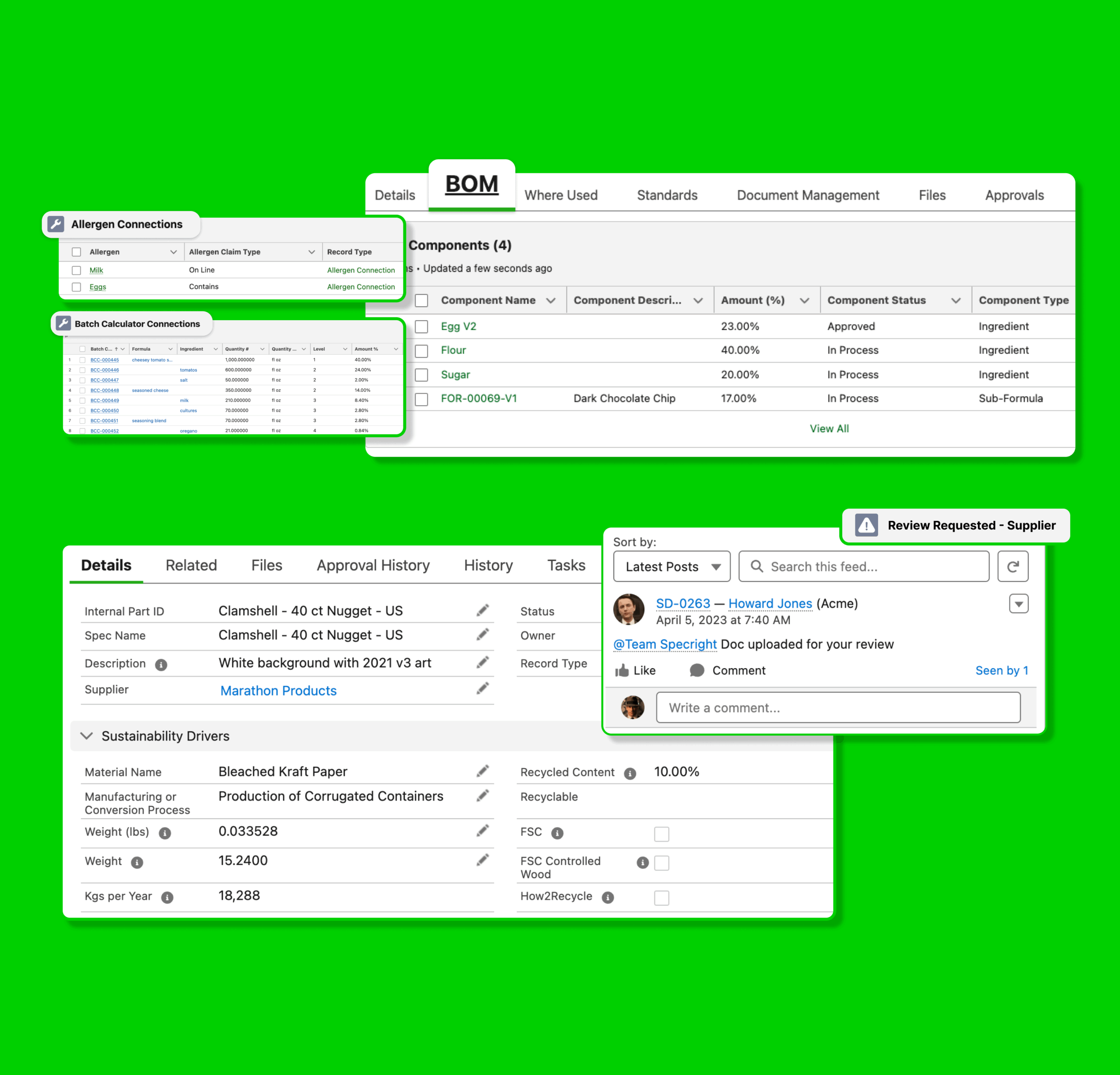

Everything You Need in One Platform

Packaging Management

Our digital, searchable platform puts data at your fingertips – and keeps your packaging teams on the same page.

Product Data Management

Accelerate time to market with clean, up-to-date product data shared across teams and suppliers.

Supplier Collaboration

Bring suppliers into your spec-first PLM for faster collaboration with accurate, up-to-date specs and shared workflows.

New Product Development

Centralize specs, projects, and suppliers to accelerate speed-to-market.

Manufacturing Instructions

Link formulas, lines, processes, and process steps for clear, consistent execution.

Formulation, Labeling & Claims

Create and optimize formulas in one place, from concept to claims, with AI-driven automation and insights.

Artificial Intelligence

AI that actually works—because it’s built on accurate, spec-level data connected across the entire lifecycle.

PLM That Starts With the Spec

Purpose-built to manage what Food & Consumer Goods products are made of—formulas, ingredients, packaging, and BOMs. From concept to commercialization, every spec stays aligned.

2025 State of Specification Management Report

Companies are managing more complex specification data than ever—but outdated systems are holding them back. Our 2025 report reveals the top challenges facing packaging and supply chain teams today, from poor data accuracy and version control to mounting sustainability regulations.

Learn why 75% of respondents say they need better Specification Management, and how leading teams are transforming data chaos into competitive advantage.

Explore by Industry

Easily Integrate with Your Existing Systems

Discover the Impact of Specification Management

Access our free resource library, and learn how to focus your data strategy, innovate, and drive your bottom line growth from industry experts.

If you get the spec right,

the rest follows

With digitized, shareable specs, you can ensure your teams and suppliers are on the same page– at all times.