Bill of Materials Management Software

Easily manage, create, and share BOMs with a spec-first approach.

Accelerate speed to market, ensure data accuracy, and spend less time chasing data with your product data with Specright’s cloud-based bill of materials management software module, designed to optimize your entire supply chain.

Say Goodbye to Static Bill of Materials

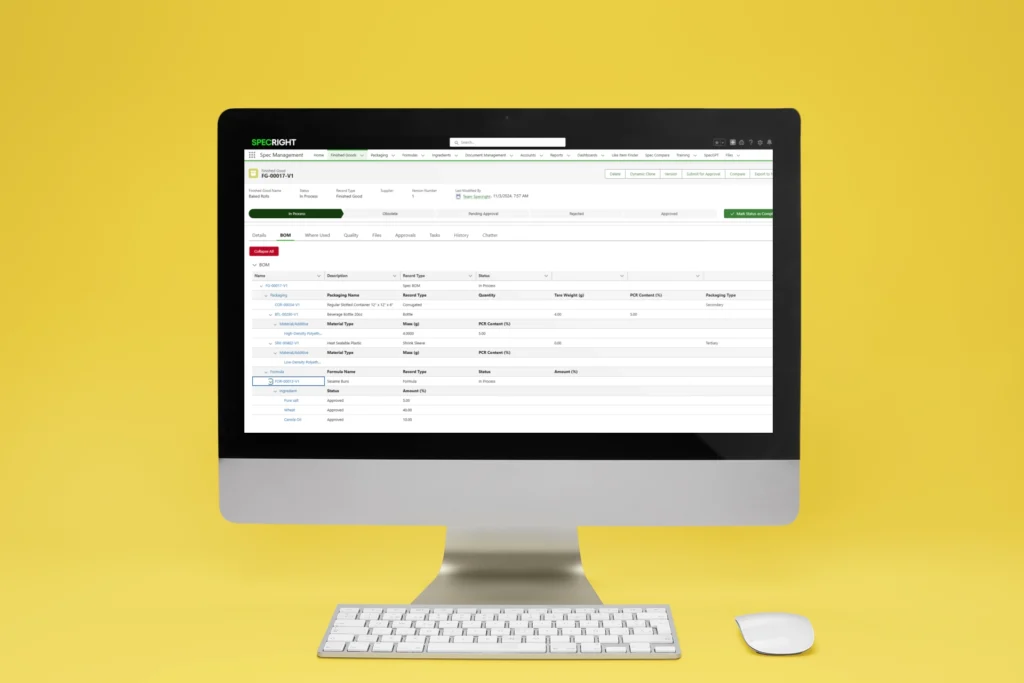

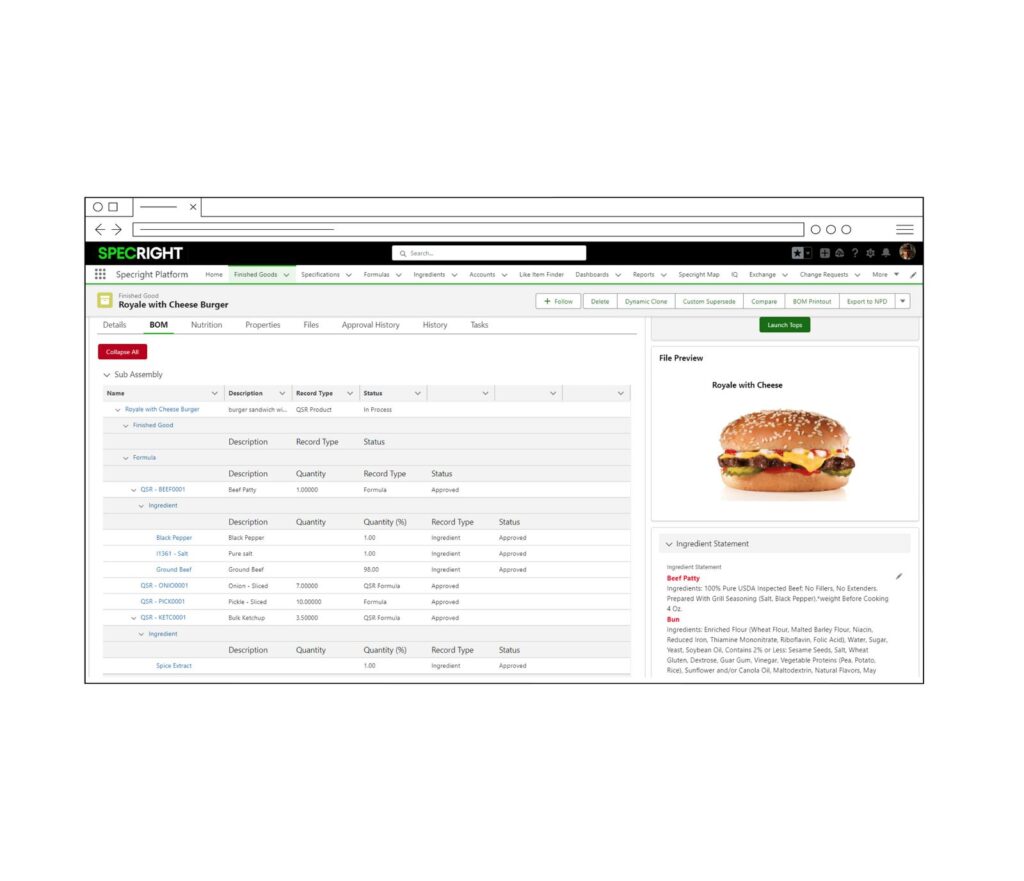

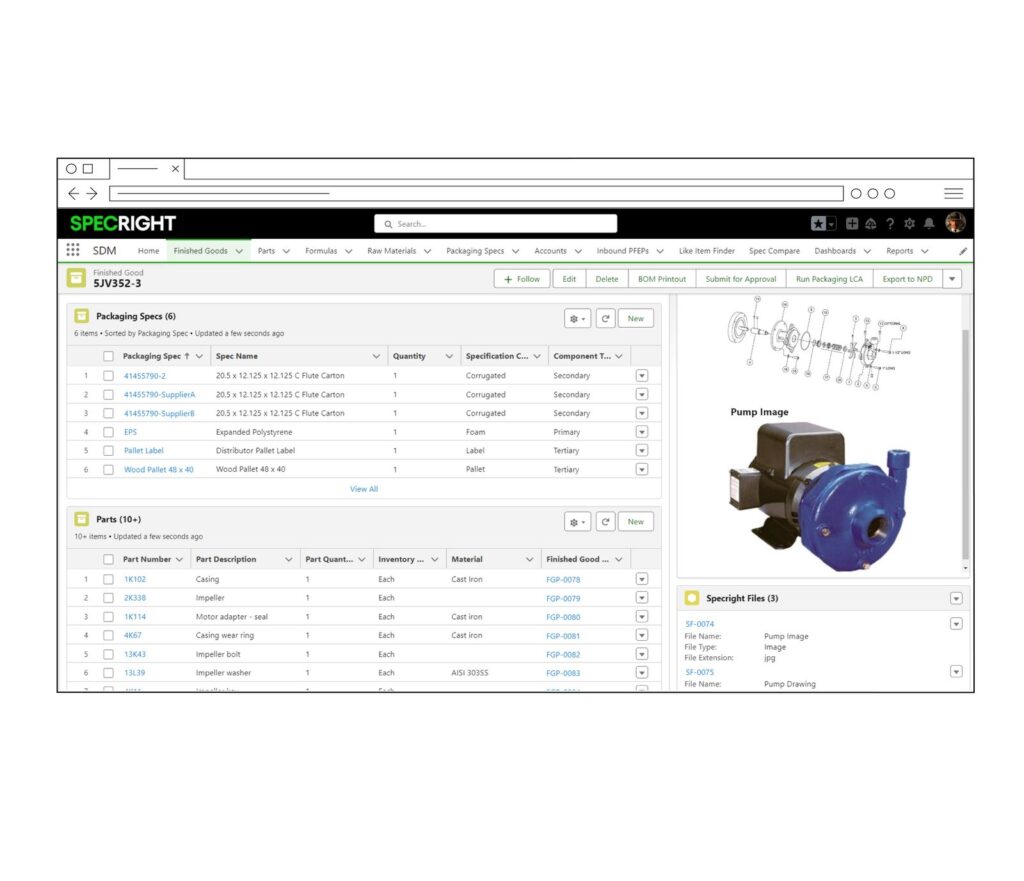

With Specright, Bill of Material management is transformed from a static to a dynamic process. You can easily link digital specs, individual parts, and components together to create a connected, intelligent Bill of Materials with real-time traceability across your manufacturing process.

Link specifications, sub-assemblies, and product components to create a Bill of Materials and Finished Products. Our patented many-to-many relationships let you see what specifications are leveraged across multiple BOMs. Manage critical data from raw materials and packaging with accuracy and clarity, enabling product development that is both efficient and innovative.

Streamline BOM Management to Accelerate Product Development

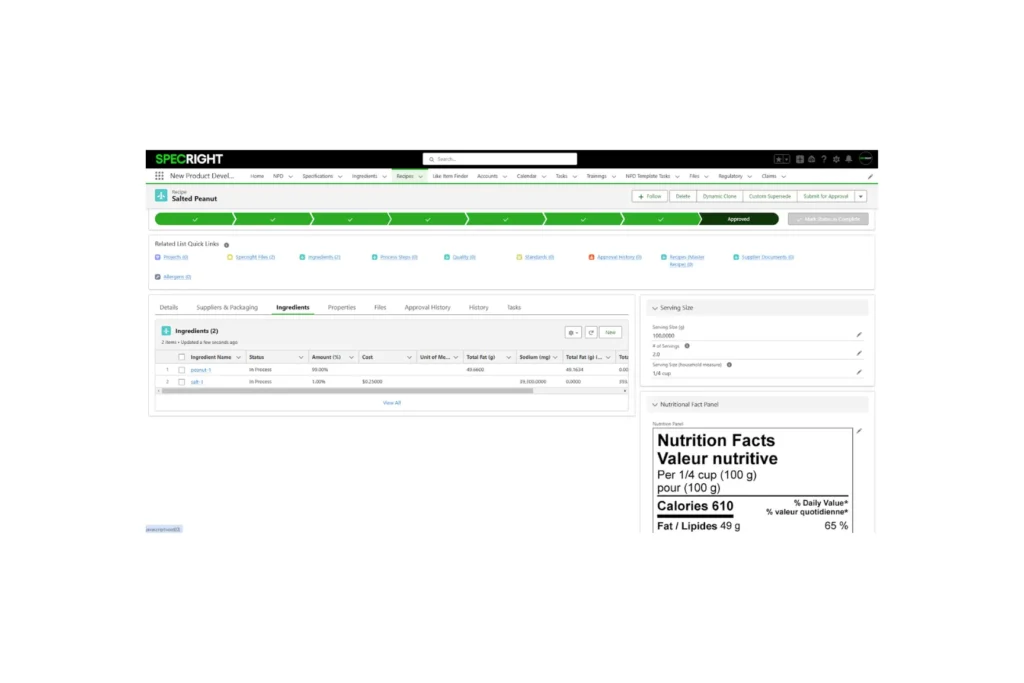

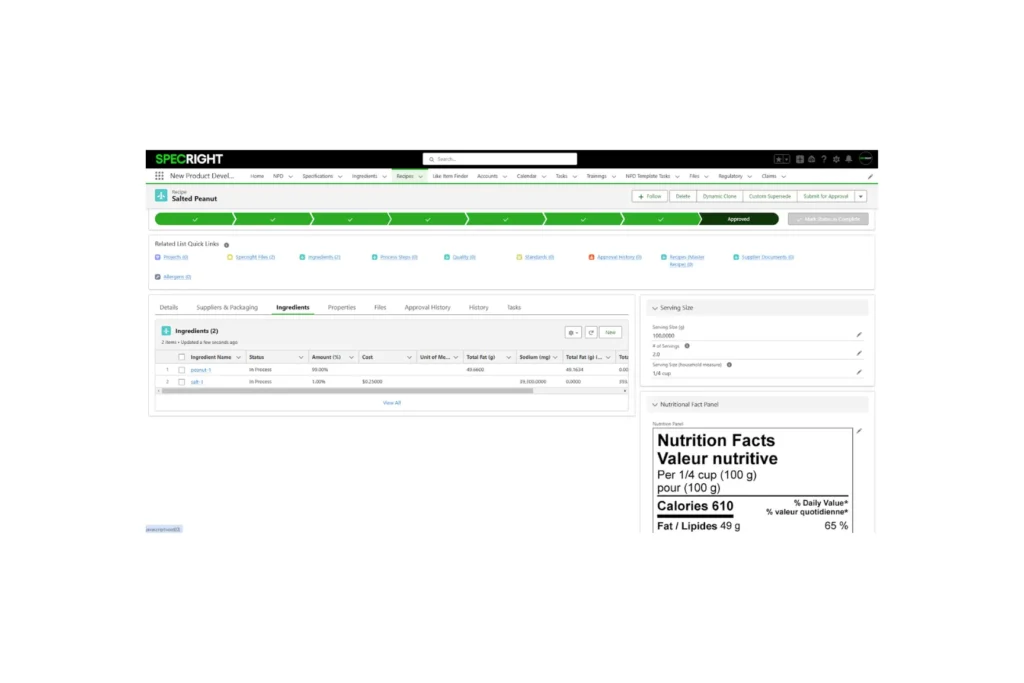

In Specright, you start with product data management and then layer on workflows to drive collaboration and approvals across teams and suppliers. By focusing on data first, you can ensure all changes are tracked across the product lifecycle, management , integrating seamlessly with your engineering BOMs and manufacturing BOMs to create a unified system that supports every stage of product development – helping you manage production and development costs effectively.

This data-first approach not only streamlines BOM management but also accelerates product development, enabling you to bring products to market faster – all while ensuring data tracking and transparency throughout the entire journey, while maintaining full traceability.

Multi-Level Bill of Materials

For complex products, you can easily manage multi-level BOMs and visualize each part with Specright’s Visual Hierarchy feature. This capability is key for ensuring both efficiency and accuracy during the product development and management cycles.

With Specright you can effortlessly track changes across multiple BOMs, ensuring an up-to-date and constant flow of product information – overall, reducing errors and increasing efficiency.

Easily Integrate with Enterprise Resource Planning

Most customers integrate Specright with their ERP solutions to pull high-level BOM details such as SKU numbers, streamlining both inventory management and pricing strategies.. The ability to easily integrate into your company’s current ERP software not only simplifies the data management process but also makes sure this data is accurate and up to date.

The connectivity between BOM and ERP data means better decision-making and operational workflows for all stakeholders.

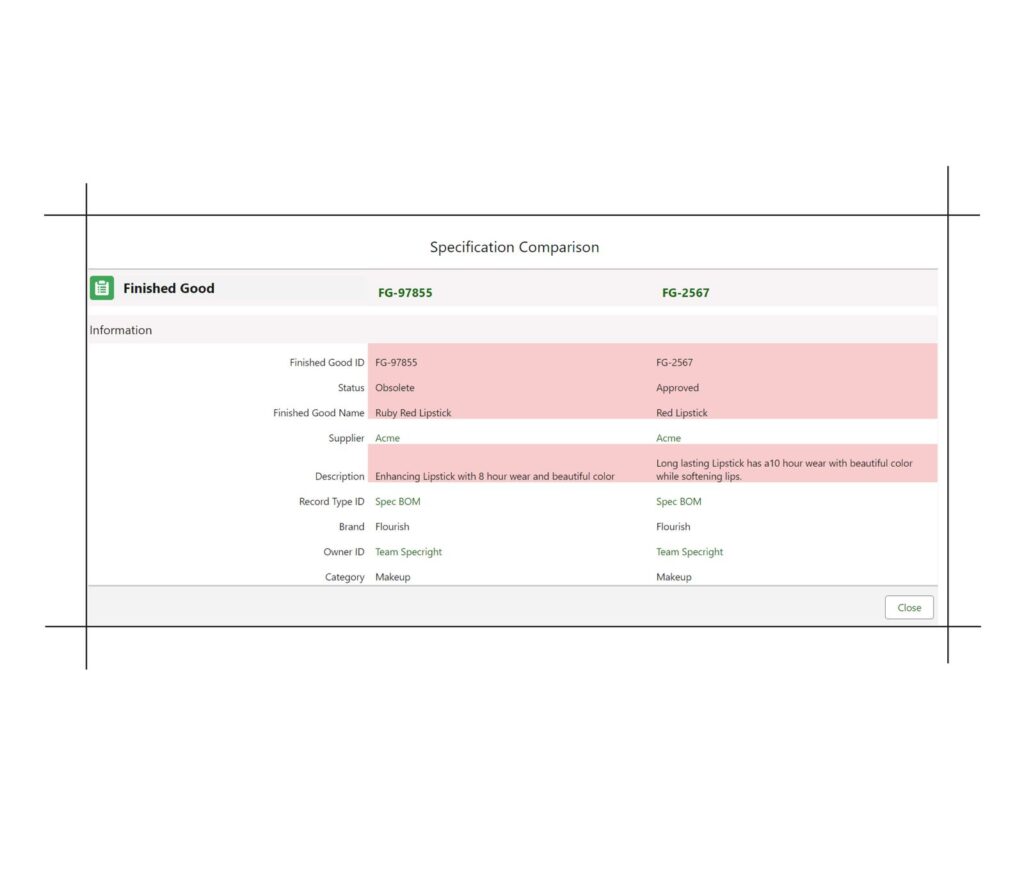

Keep Track of BOM Versioning

Products are changing all the time, which means the need for up-to-date BOMs is more important than ever. With Specright, you can easily track revisions and new versions of BOMs, ensuring that all related documentation is current and accessible.

With constant accurate data, all stakeholders will have access to the most current and necessary information. In an ever-evolving product landscape, Specright’s version control capabilities are essential for maintaining the integrity of your BOMs, reducing errors, and ensuring seamless updates across the board.

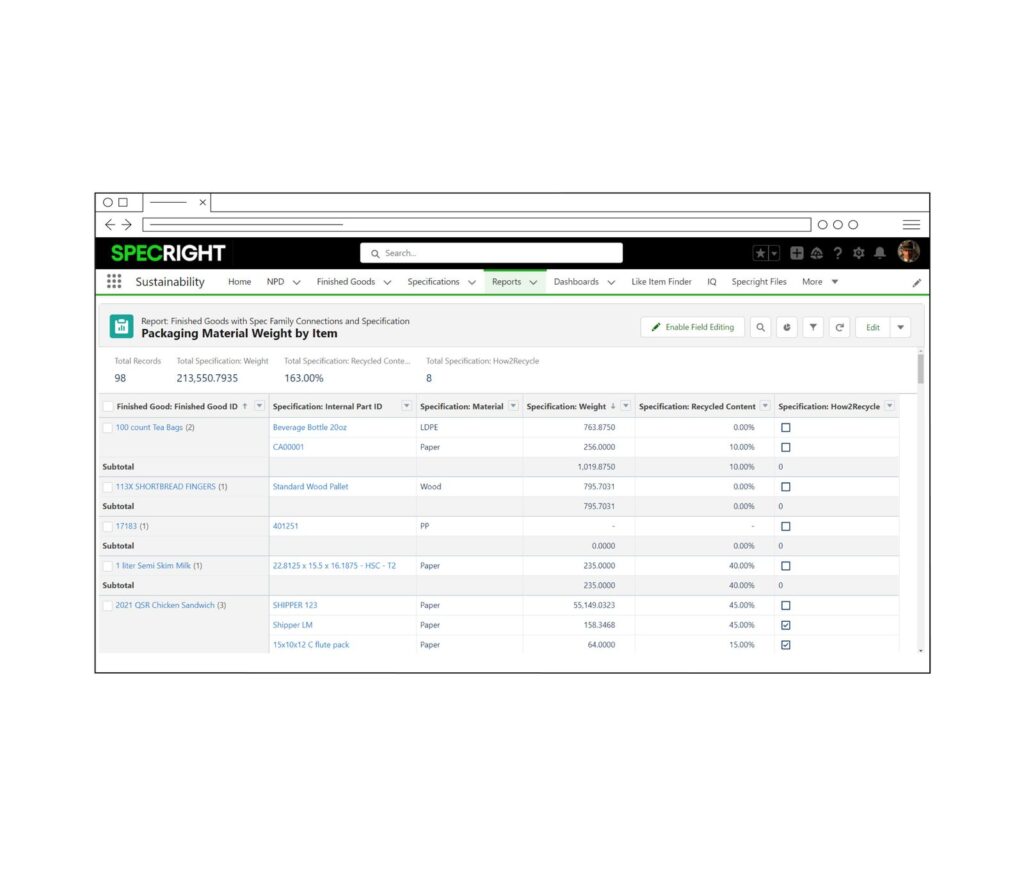

BOM Management Software Solution Across Industries

Specright’s software is used by manufacturing companies across food & beverage, consumer goods and beauty, industrials and life sciences industries – its versatility is far-reaching. This adaptability allows you to manage different types of BOMs, from engineering BOMs, manufacturing BOMs, packaging BOMs, and more.

Specright’s adaptability across various sectors underscores its comprehensive and forward-thinking approach, making it the go-to solution for companies of all sizes.

BOM Structure and Data Connectivity

With a robust and interconnected framework, Specright offers the highest value approach for BOM structure and data connectivity.

Access to data across teams and sectors allows your company to maintain clear and consistent BOM structures, empowering unified decision-making and a seamless flow of information.

If you get the spec right,

the rest follows

With digitized, shareable specs, you can ensure your teams and suppliers are on the same page– at all times.