What is Product Specification Management?

Product specification management is the discipline of managing all of the data needed to make a product and its related components, such as packaging, raw materials, formulations, ingredients.

Over the past decade, managing product specifications has become increasingly important. Consumer demands for different products has led to SKU proliferation, which has resulted in an explosion of product specifications that companies must manage throughout the product development process and across their supply chain.

But the principles of product specification management are more than just managing data. It’s about managing relevant templates, workflows, automation, regulatory constraints, and stakeholders that ultimately result in a final product.

Historically, most companies have managed this granular level of product data in excel spreadsheets, PLM systems, and quality management software. This is especially true for packaging specifications, which today are necessary for sustainability reporting and regulatory compliance, such as the UK plastics tax in Europe and extended producer responsibility laws.

Managing this data in legacy systems is no longer feasible – it slows time to market, frustrates product teams by distracting from business needs, and results in supply chain teams focused on data management instead of product innovation.

The Importance of Data Management Across the Product Life Cycle

For any business, bringing a new product to market requires investment. And with some reports citing that almost half of all new products fail, the stakes are high in not wasting any resources throughout the process.

Wasting time, resources, and money can make experiments larger failures – and should be avoided. You can create efficiencies during product design by implementing basic project management, document management, and most importantly – specification management.

How to Use Data During Product Development

For product teams, the best source of product ideas often come through customer feedback.

But it can be hard to balance these ideas with current business initiatives, which means many of these ideas fall through the cracks. It doesn’t have to be this way.

Many companies are now storing new product ideas and associated product information in a specification management system. This enables them to have an “innovation library” of sorts, where they can digitize product information for historical record and easily search to find the next great item to include on their roadmap.

Why Specs are Important for Product Development

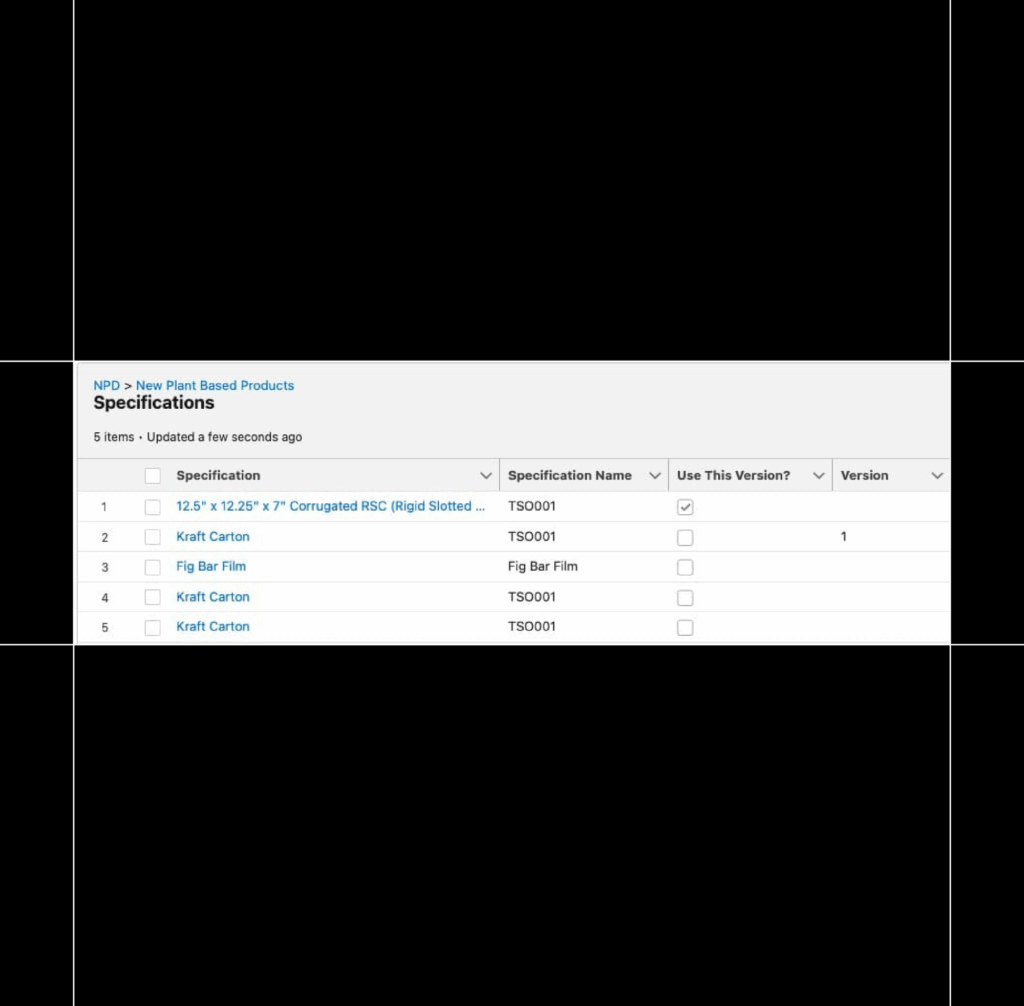

Managing specs is also critical, especially when dealing with multiple product lines. When team members can reference a single source of truth, it streamlines workflows and reduces emails back and forth to confirm the “correct” product specification. This is especially important for product teams in food & beverage, cosmetics, and CPG, where formulas might be regulated or where disclosures are required around allergens.

Using a Product Specification Management System

When companies centralize their product information, they enable their development team to spend less time chasing data and more time making amazing things.

Today, product specs touch more departments than ever and some of this data often lives with suppliers, especially for things like packaging components.

By using specification management software, companies can easily manage all product-related data in one place.

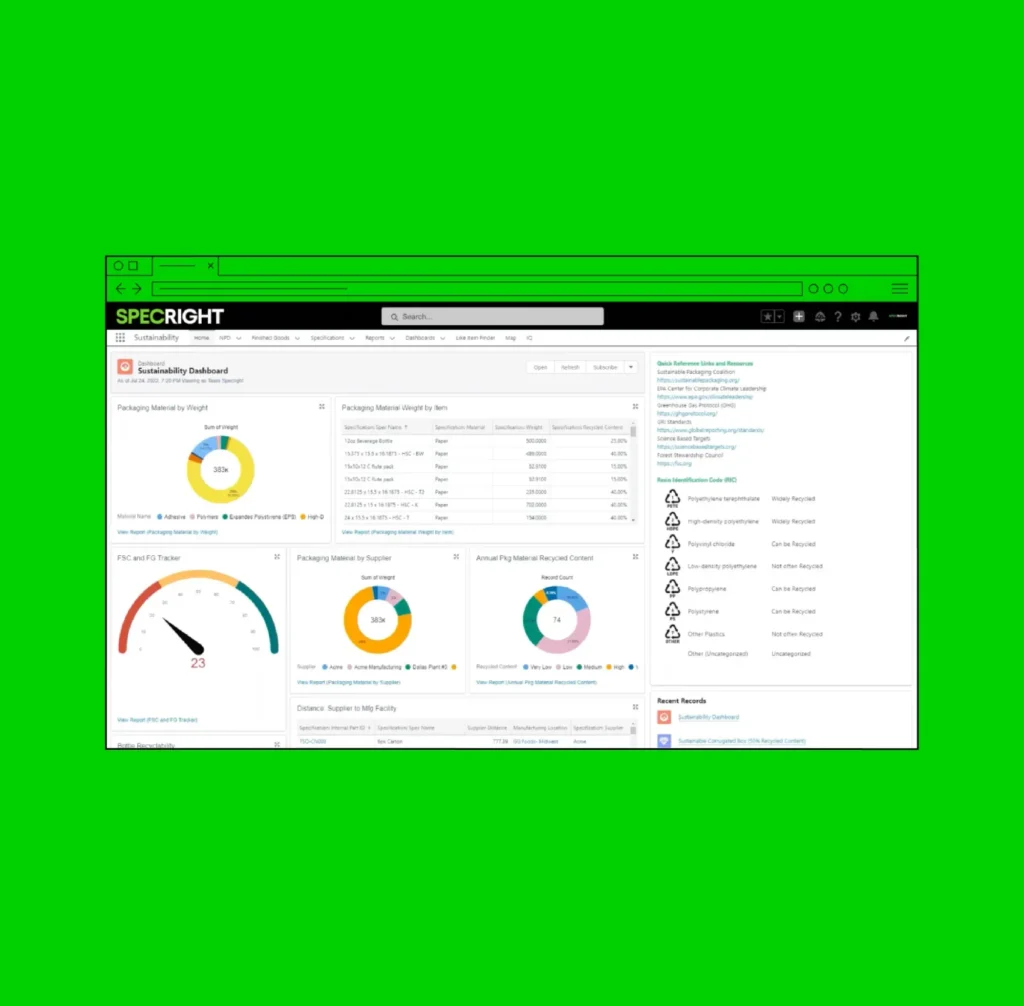

At Specright, our spec-first approach focuses on the digitalization of product specifications. This means digitizing every field so specs are searchable, traceable, and reportable.

Furthermore, linking these specs provides supply chain traceability and reduces data duplication. For example, if one ingredient changes – and it’s linked to multiple products – there’s no need to go into each product individually to make updates.

If you get the spec right,

the rest follows

With digitized, shareable specs, you can ensure your teams and suppliers are on the same page– at all times.