Digitizing product and packaging specifications into a centralized system

Specification Management is the process of building and collecting DNA-level information, or specifications, for products and packaging into a centralized system. Specification Management is the key to making products and packaging efficiently while also mitigating risks.

Specright’s purpose-built platform solves 3 fundamental problems

A lack of common language around specifications

A lack of common language around specifications often results in miscommunication, errors, and SKU proliferation. Without a templated approach to spec creation, it’s challenging to work efficiently and get teams on the same page.

Incomplete data or a lack of critical components

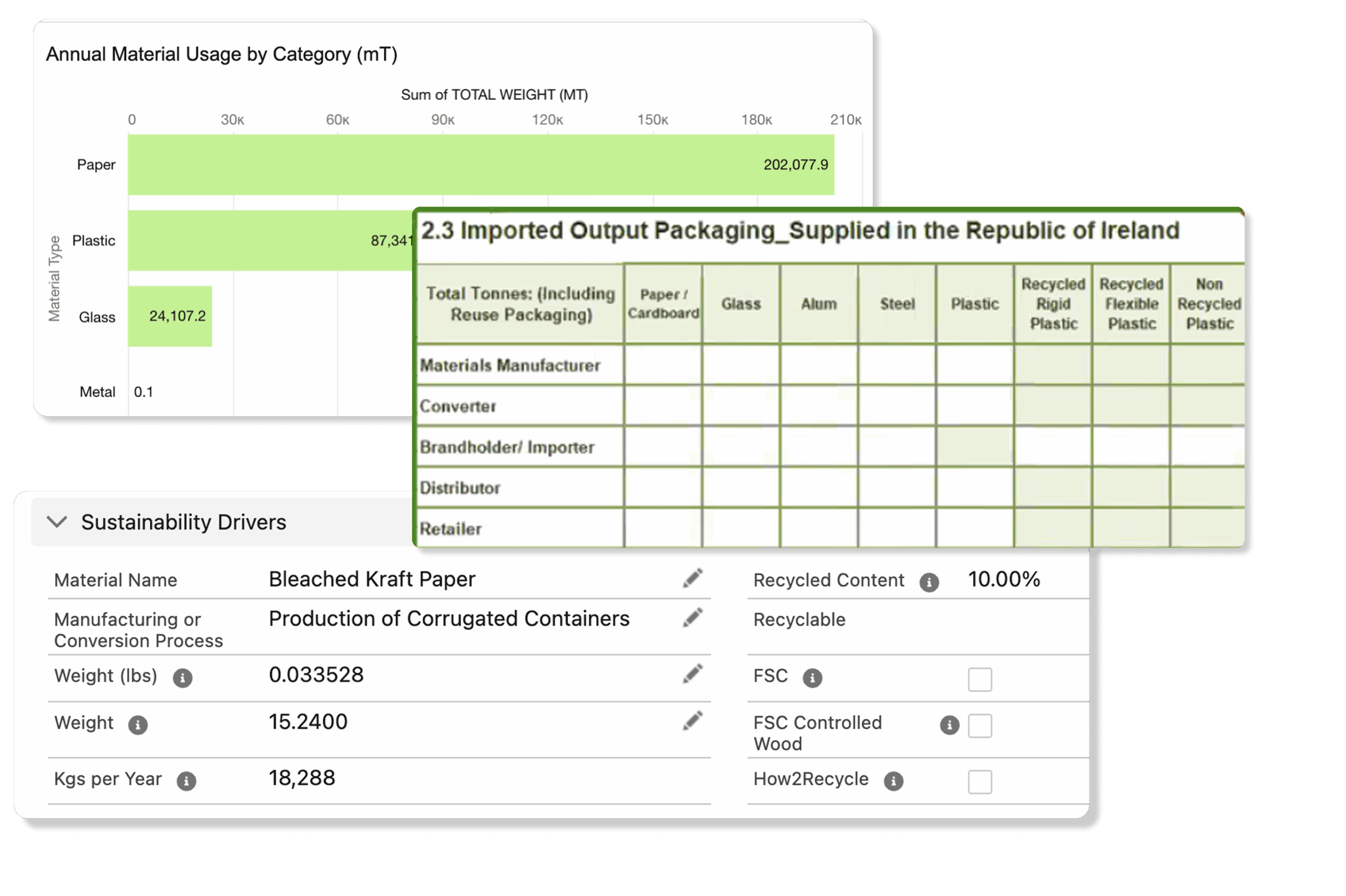

Data is often owned by many different departments and suppliers. Without a central source of information that updates in real-time to all necessary stakeholders, teams must manually request and search for data across other departments and suppliers. When all necessary product and packaging data is not readily available, it’s difficult to manage Bills of Materials (BOMs) and slows speed-to-market.

The inability to share up to date information

Before Specification Management, sharing specs often occurred via static formats, from emails, to spreadsheets, and even pen and paper. This made it virtually impossible to collaborate across departments and supply chains, as well as inhibiting supply chain visibility and traceability.

Revolutionizing supply chain collaboration with patented technology

Chasing data is old news. Specification management is not. Specright built the first patented Specification Data Management™ (SDM) platform of its kind.

Without Specright, specification data is typically housed in an array of static systems—whether it’s email, spreadsheets, legacy systems, or shared drives. These static systems often result in siloed data that lacks the accessibility and standardization needed to function as a source of truth for the supply chain, inhibiting collaboration.

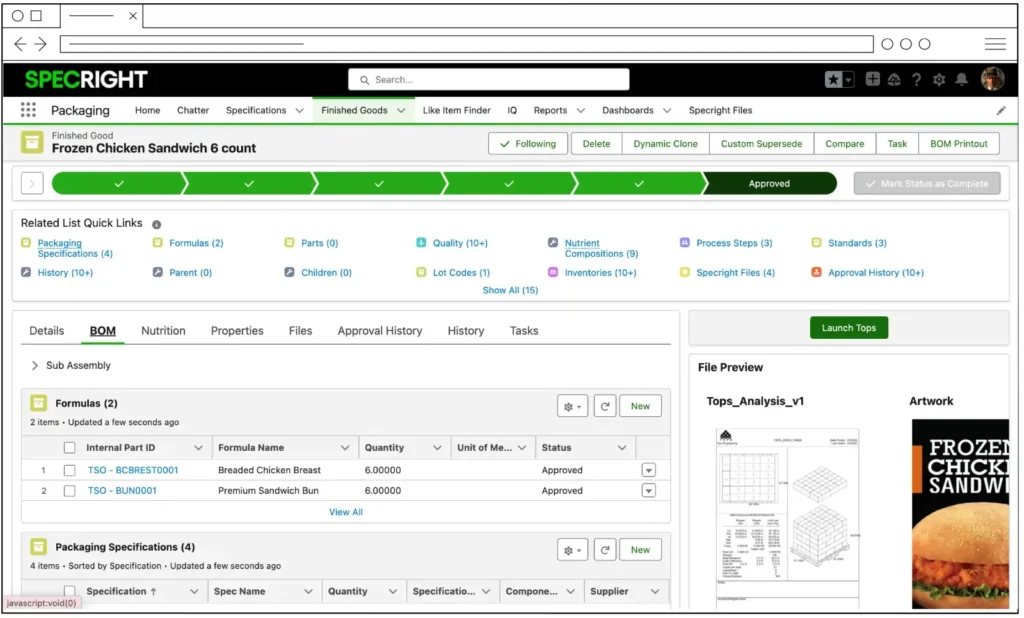

The many-to-many relationship structure of the Specright platform enables companies to link together all the data related to making a product, from its packaging, quality, and manufacturing specifications and more.

Frequently asked questions

Have questions? Check out the FAQs. For any questions not listed, reach out to us via our ‘Contact Us’ form.

What is Specification Management?

Specification Management is the process of building and collecting DNA-level information for products and packaging into a centralized system. When you digitize and link specifications together, you create visibility and traceability across your supply chain. This makes it easy to layer on workflows, approvals, and processes. It’s not enough to simply digitize specifications; they need to be mapped and interconnected to drive intelligence. Specification Management also enables you to achieve outcomes like from improved supplier collaboration, sustainability, consolidating SKUs, and more.Specification Management is also the title of the software category that Specification Data Management platforms are housed in.

What is Specification Data Management?

Data is often owned by many different departments and suppliers. Without a central source of information that updates in real-time to all necessary stakeholders, teams must manually request and search for data across other departments and suppliers. When all necessary product and packaging data is not readily available, it’s difficult to manage Bills of Materials (BOMs) and slows speed-to-market.

Why is specification management software important?

Before Specification Management, sharing specs often occurred via static formats, from emails, to spreadsheets, and even pen and paper. This made it virtually impossible to collaborate across departments and supply chains, as well as inhibiting supply chain visibility and traceability.

Discover the value of Specification Management

2025 State of Specification Management Report

Companies are managing more complex specification data than ever—but outdated systems are holding them back. Our 2025 report reveals the top challenges facing packaging and supply chain teams today, from poor data accuracy and version control to mounting sustainability regulations.

Learn why 75% of respondents say they need better Specification Management, and how leading teams are transforming data chaos into competitive advantage.

Specification Management Adoption Guide

Learn about:

Discover the Impact of Specification Management

Access our free resource library, and learn how to focus your data strategy, innovate, and drive your bottom line growth from industry experts.