When it comes to managing data and specifications for every product and package, companies can run into many roadblocks and complexities. With endless data streams and product SKUs having a detailed plan and management system for all this data is crucial. And that’s where Plan for Every Part (PFEP) comes in.

What is Plan for Every Part (PFEP)?

Simply put, PFEP is a lean manufacturing concept that strives to help companies manage every part of their supply chains, from individual ingredients and materials to packaging and any other part information.

By encouraging companies to create a detailed plan for all these elements teams can strive for continuous improvement internally and externally. PFEP empowers companies to optimize their material flows and track inventory levels and part numbers, improving overall operational efficiency.

Although with this being said before companies can implement proper PFEP practices they are going to need to track down all necessary specification data to provide a solid foundation for the rest of the process.

Specification Data is the driving force of PFEP which means that companies using legacy systems such as Excel or non-purpose-built systems like ERPs or PLMs are going to struggle when it comes to building out their PFEP database.

How Plan for Every Part (PFEP) Works

As mentioned before, PFEP is all about creating a plan, and not just any plan but one that is both detailed and comprehensive and can be utilized cross-functionally.

To create this plan companies must first identify all of the necessary parts used in a company’s manufacturing and production system. During this step, each individual product is allocated a unique identifier and specifications for inventory management.

With the collaboration of all team members and stakeholders specifications and technical requirements are digitized and mapped. This means gathering all data related to the part number, description, part weight, material handling, and much more.

The crucial data collected with PFEP strategy then works to analyze demand patterns, lead times, and production schedules to determine optimal inventory levels for each part and finished good.

Goals of Plan for Every Part (PFEP)

At the end of the day, PFEP is not a one-stop shop – it requires continuous improvement of real-time data, monitoring, and adjustment to shifting environments.

Companies looking to implement PFEP should always be striving for continuous improvement and optimization of current and new products.

What worked for managing a company’s supply chain 12 months ago is likely going to need some changes. In-depth reviews and analysis of supply chain processes are critical in addressing the plan’s effectiveness.

Advantages of a Plan for Every Part (PFEP)

All this considered there are a few standout advantages that can accompany the implementation of plan for every part – if it is done right.

1. Inventory Control

With PFEP processes, benefits related to inventory control will stand out. This is because, with PFEP in place, insights into inventory levels are accessible supporting teams in avoiding shortages while reducing the need to store extra inventory.

Not only does this ensure that companies can fulfill order quantities but also reduces costs related to carrying and storage of products.

2. Predicting Demand

On top of running successful production control insights into inventory levels and order quantities allow teams to analyze demand patterns. Understanding these patterns gives companies the opportunity to create demand forecasts and estimate lead times.

It’s all about historical data – data that allows teams to identify trends related to a part’s consumption. By understanding past raw material usage and demand, teams can further ensure inventory levels are in check.

Ultimately inventory control and predicting demand go hand and hand – both achievable with the company-wide implementation of the plan for every part methodology.

3. Supply Chain Visibility

If you haven’t heard us say it before, it’s the data and specifications that provide visibility into your supply chains. And visibility is a must when it comes to successful lean manufacturing and supply chains.

By creating one-source-of-truth for all parts and components within your supply chain teams are empowered to make informed decisions about material flow, improving the overall value stream.

Optimizing supply chain functions with data in one centralized system enables stakeholders to quickly find the necessary details about any part of their supply chain.

The ability to locate part details means that essential team members can efficiently identify parts that need replenishment – before inventory is low and orders are halted.

4. Improve Sourcing

This improved supply chain visibility also gives companies the opportunity to address areas of improved sourcing and supplier relations.

For PFEP to be successful, close collaboration with suppliers is a must. Suppliers should be able to access and provide all necessary data related to part specifications, lead times, and product procurement.

Access to supplier information and specifications can help teams determine which suppliers are best, to optimize storage location and reduce transit times.

And on the other end, data transparency provided to suppliers ensures that they feel empowered to meet demand and adjust production capacities accordingly.

Challenges of Plan for Every Part (PFEP)

For many companies the challenge is not creating the plan itself, it is locating the necessary data and specifications to make this plan successful.

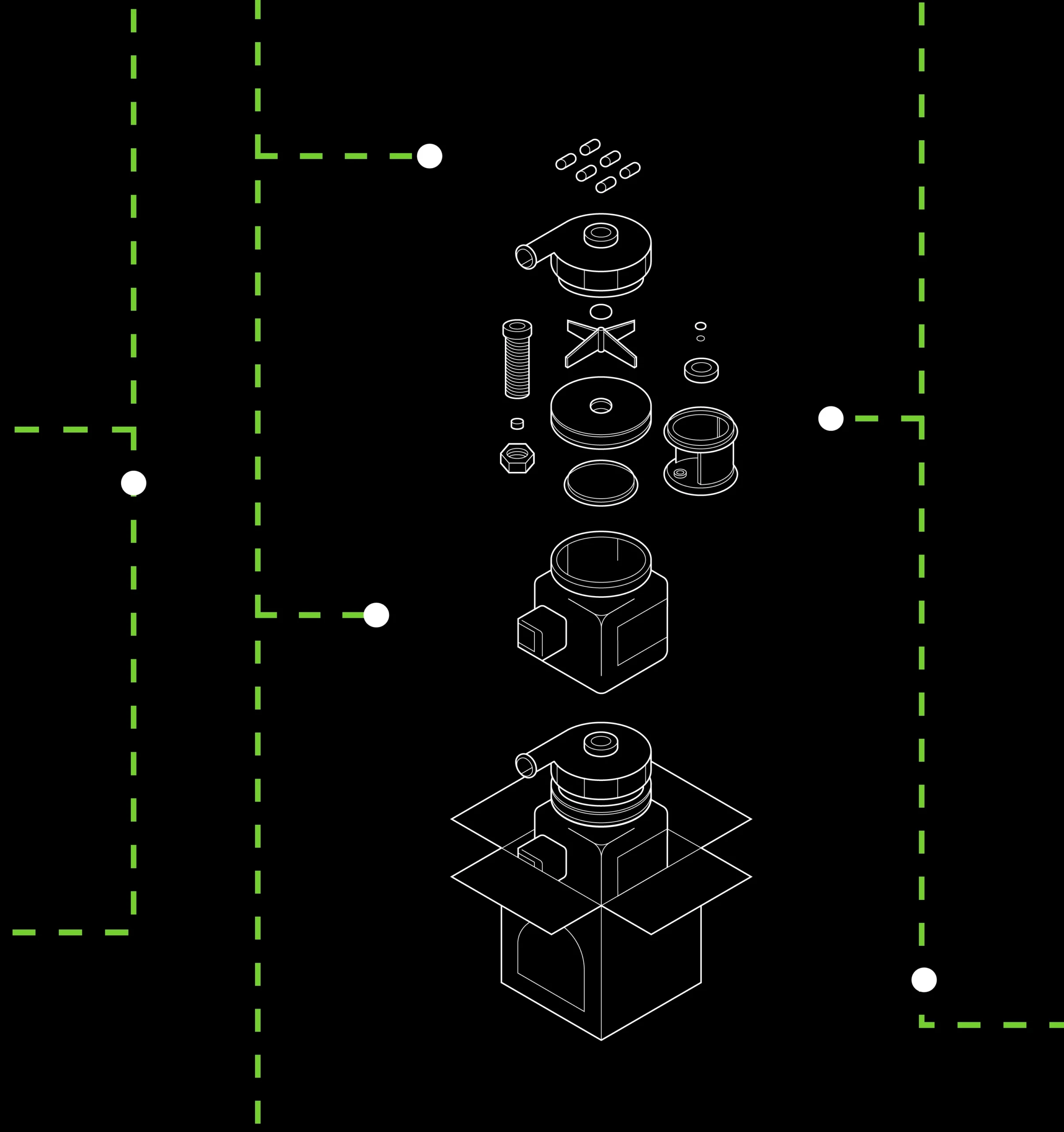

For PFEP to fulfill its full potential linking and connecting specs to form sub-components or sub-assemblies is a necessary process that legacy and non-purpose built systems lack the data to do.

And prior to even making these connections companies must ensure that they have access to accurate and up-to-date data – including part information, inventory levels, and supplier details.

When data is stored in various legacy systems or run by different teams using manual data entry processes, centralizing this information to create the plan in the first place can be the most difficult part.

It’s time to ditch these systems in order to reap the benefits of plan for every part – and as we mentioned above these are not benefits you want to miss out on.

How a Spec-First Approach Transforms Plan for Every Part (PFEP)

Without a solid foundation of specifications related to products and packaging developing a PFEP strategy will be near impossible. As we discussed above in order to optimize supply chain functionality and take advantage of the power of PFEP visibility into data is a must.

For companies taking a spec-first approach, well-defined and detailed specifications will already be accessible and will help ensure that the data used in PFEP is accurate and up to date. With clear part specifications, teams developing PFEP strategies can define each part in much more detail.

Both internally and externally, access to live specs ensures that everyone is aligned and working towards a common goal – backed by data-driven decision making.

From improved part management and reduced waste to optimizing inventory levels and enhanced collaboration, the implementation of a spec-first approach for PFEP will transform the process’s impact on your company.

To learn more about how your team can simplify the complex with a spec-first approach to plan for every part make sure to download the eBook here.

Explore More Blogs

Get Started

With Specright’s Solution Suite, you can digitize, centralize, and link your specification data to drive efficiencies, intelligence, traceability, and collaboration within your organization and across your supply chain network.