Many companies don’t have a solid understanding of the relationship between their supply chain and sustainability, or an easy way to identify opportunities to improve both.However, a DNV GL-Business Assurance survey revealed that 86 percent of companies feel mounting pressure from stakeholders and consumers to investigate how they can make every stage in their supply chain more sustainable.In response, companies are turning to Specification Data Management (SDM) software to give them greater visibility into their supply chain at the specification level. The purpose is to better identify issues that are preventing or delaying sustainability goals and take a proactive stance in making impactful changes. Here’s how SDM can help.

1. Favor Sustainable Supplier Management

One of the benefits of dialing down to the specification level is that it allows you to see the source of your materials. Before SDM, this process was largely done by hand and inefficient, time-consuming, and costly. Now, SDM software facilitates sustainable supplier management by helping you compare material sources for all products from a single platform in seconds.You may find that some of your vendors offer the same or comparable materials to other vendors and better align with your sustainability initiatives. Taking advantage of these opportunities can help you improve your own standing in the process.

2. Build a Culture of Sustainability

Specright believes that empowering employees to take action on sustainability is just as important as setting goals. SDM software’s user-friendly interface makes it easy for more employees to take a proactive stance with sustainability. Use of the software can help save time when searching for specification information and the data can be accessed and used by multiple employees and/or suppliers simultaneously. That means companies are better positioned to build a sustainable mindset into the corporate culture that allows everyone to participate.Implementing such a software product is a direct reflection of the company’s organizational goals, mission, and values. It can also help companies build communication strategies and processes around sustainability, including the creation of a supplier Code of Conduct.

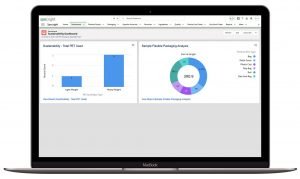

3. Track Sustainability Progress

As you’re making these sustainability-conscious decisions, SDM software can help you track your progress automatically, including savings-to-date and waste reduction. As a result, you have thoughtfully created, data-driven proof that you can provide to shareholders and consumers to show where you’re moving the needle and the steps you’ve taken to reach your current level of sustainability.Opportunities to improve sustainability don’t always manifest themselves on their own. Rather, by focusing on the specification level and working outward, companies are better able to identify key areas that can help them continue moving forward. Download our ebook to learn more about how SDM technology can help your company meet its sustainability goals.

4. Maximize Human Resources

Sustainability, by definition, can refer to two different things in the supply chain. There’s the act of avoiding depletion of natural resources or otherwise making a negative impact on the environment. Then, there’s the ability to maintain performance at a certain level over a period of time.The latter includes how companies effectively leverage one of their most precious resources: people. SDM allows you to avoid recreating the wheel every time you need to design a new package or product. In many cases, SDM tools can help you find the specifications you need to satisfy different projects without creating a new SKU. In turn, avoiding these unexpected and unnecessary time wasters can allow you to do more with your existing resources – which might include figuring out how to make your products or packaging more sustainable.

For more information on how Specright and Specification Data Management can help you make your supply chain more sustainable, download our ebook.

Explore More Blogs

Get Started

With Specright’s Solution Suite, you can digitize, centralize, and link your specification data to drive efficiencies, intelligence, traceability, and collaboration within your organization and across your supply chain network.