Specification management is paving the way for end-to-end digital supply chain management. And not a moment too soon – the world is demanding supply chains to be dynamic, flexible, and able to respond in real time, but most current methods of managing the supply chain can’t keep up. And we get it – when it comes to the supply chain, there’s a lot at stake. You need a system with proven value that will get you results. That’s why companies are turning to Specification Management software.

What’s the ROI of Specification Management?

As executives evaluate implementing Specification Management software across their enterprise, the conversation naturally turns to return on investment (ROI).

The good news is, the returns abound. At Specright, we conducted a research report with – and the numbers speak for themselves (spoiler alert: the ROI of specification management is 469%). Here’s why.

How Specification Management Software is Driving Efficiency and Improving Your Bottom Line

Supply chains have become increasingly complex and no industry is immune. Manufacturing, food and beverage, beauty and cosmetics, consumer packaged goods, and packaging supply chains are more global and disparate than ever. Navigating global business operations, broader logistics networks, ever changing global trade regulations, and expanding product portfolios has revealed the need for better supply chain data management.

But companies needed a software purpose-built to manage the root cause of these challenges: a lack of specification data management. Everything is a spec and everything has specs, but today’s supply chain solutions are designed to manage high level data and processes – making it easy for errors and waste to slip through the cracks.

Specification Management software positively impacts many stakeholders and departments, for example:

But we know it’s not easy to simply reengineer your tech stack. Luckily, spec management fills critical gaps and can be used in conjunction with the software you have in place already. Let’s get into the details.

Cost Savings and Business Benefits Enabled by Specification Management

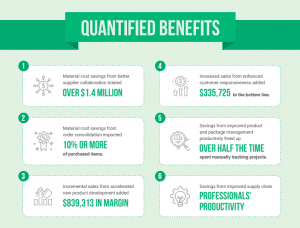

Forrester helped us narrow down the top 6 benefits and functionality companies gain when using Specright’s Specification Management Platform (check out the full benefits list by accessing the Forrester Report here).

1. Cost Savings from Better Supplier Collaboration

When company’s deploy Specright, they gain a single source of truth for packaging and product data.By enabling companies to centralize and maintain the most accurate, complete, and up-to-date specifications, they’re able to work hand-in-hand with their supplier network to manage and reduce material costs.

Additionally, Specright makes it easy to bring in new, smaller, and more specialized suppliers to the vendor pool, making the bidding process more competitive and helping businesses take advantage of advancing technology in the supplier community. During COVID, many Specright customers were able to quickly onboard new suppliers and get them up and running simply because they had their data at the ready.

2. Order Consolidation Cost Savings

With Specright, it’s easy to spot order consolidation and rationalization opportunities. By housing specs centrally in Specright, companies are able to rationalize packaging SKUs, identifying nearly identical items ordered by different teams or plants and eliminating duplicates. This also increases price reductions due to larger orders of one spec.

Further, companies can identify items that suppliers can run in combination for quantity discounts. Forrester estimates that one-third to one-half of these combination run opportunities get missed. In Specright this can be proactive. For example, a person placing an order can be prompted to consider ordering other relevant parts in combination. In fact, one of our customers has been able to routinely benefit from lower costs on 350 different packaging items.

3. Increased Sales Due to Accelerated New Product Development

Having a complete and reliable source of specifications available kickstarts innovation efforts. Develop and commercialize new products more quickly by consulting Specright for similar finished products and materials from approved suppliers or using specification templates. With all of this data at your fingertips, build a bill of materials quickly and easily – you can use existing agreements or inventory to get the product to market fast without concerns about compliance issues or recalls. One of our customers said that Specright has helped them identify slower moving inventory, which enables them to adjust their marketing strategy of those items to better respond to consumer trends. This is critical for companies competing in today’s consumer goods market, where there’s major competitive advantage to be able to respond consistently to rapidly evolving trends.

4. Increased Sales Due to Enhanced Customer Responsiveness

Amazon created a world of instant-gratification consumerism – and companies have to be prepared to respond rapidly to survive. One customer in the food and beverage industry put it this way when talking about private label sales: “You must be able to turn a product over to meet a sales expectation because you don’t get those opportunities every day. Somebody else has filled that need if they’re able to respond more quickly than you are, speed to market is critical.”

To stay ahead of the competition, organizations need to be able to instantly access granular packaging and product specifications. In Specright, this data is always a few clicks away. Easily grab detailed specs from your product and packaging portfolios, so you can clone and quickly iterate data into new products. You can also access other information you need to streamline the product to market process such as: labeling, quality control standards, manufacturing processes, raw materials, sustainability information and more.

5. Improved Product and Package Management Productivity

Today’s consumers demand increasing product customization, leading to rapid innovation and SKU proliferation.Specright can help mitigate additional costs by streamlining the product development process.

For example, a Specright customer in the packaged fresh foods industry was able to avoid hiring additional project managers even though the team’s workload nearly tripled. He explained: “Right now we have close to 300 product changes going on. We have people from all functions involved, and external partners like third-party marketing agencies and pre-press houses. Keeping track of all those moving pieces and all those participants is very, very challenging.”

He used Specright’s Specification Management System, where they already stored the specifications for these new products and promotional packaging, to accelerate workflows and facilitate interdepartmental collaboration much more efficiently.

6. Savings from Improved Supply Chain Professionals’ Productivity

Supply chain productivity is a huge catalyst for companies seeking spec management solutions. There’s a critical need for information about specifications, and time and energy supply chain professionals spend chasing data creates a ripple effect of inefficiency, waste, and risk. With Specright, data can be pulled in minutes, by anyone with access. This enables job autonomy and frees up time knowing you don’t have to wait around for that email with the data you need to do your work.

How to Achieve Your Business Goals With Specright’s Specification Data Management Platform

For more information on the full list of benefits, costs, and how to implement Specification Management at your organization, download the full Forrester report or reach out to a member of our team.

Explore More Blogs

Get Started

With Specright’s Solution Suite, you can digitize, centralize, and link your specification data to drive efficiencies, intelligence, traceability, and collaboration within your organization and across your supply chain network.