For many companies, year after year, product requests increase, new SKUs are developed, and customers demand additional product variation. Meeting these demands through expansion allows companies to cater to different customer profiles, although, with new products and potentially new customers in the mix, data increases and operations become more complex. Companies using specification management systems to control this rise in data will find this shift seamless, but for companies who rely on legacy or non-purpose-built systems, data challenges will continue to inhibit innovation.

Hundreds of Requests, Lost Specifications, and Not Enough Time

Ocean Mist Farms is the largest grower of fresh artichokes in North America, with farms in Castroville, Oxnard, Coachella, and Baja CA. The family-owned business also grows a full line of vegetables and continues to ensure that its crops are of the highest quality and meet consumer demands.

Each year the company receives hundreds of requests for new products from their customers, although with inadequate management systems and limited team members, meeting these requests is no simple task.

With legacy systems in place, processing, managing, and bringing these products to market was nearly impossible for Ocean Mist Farm’s product development team and that is why they got in touch with Specright.

Saving Time and Eliminating Duplicate Data

As Ocean Mist Farm’s Packaging and Sustainability Manager, Laura Berlanga’s time spent searching for specifications was valuable time lost for all her team members – a realization that many of our customers come to.

Brainstorming and innovation were replaced with data mining which was unsuccessful time and time again. Data was stored across various legacy systems and many times Laura was unable to access the data when found.

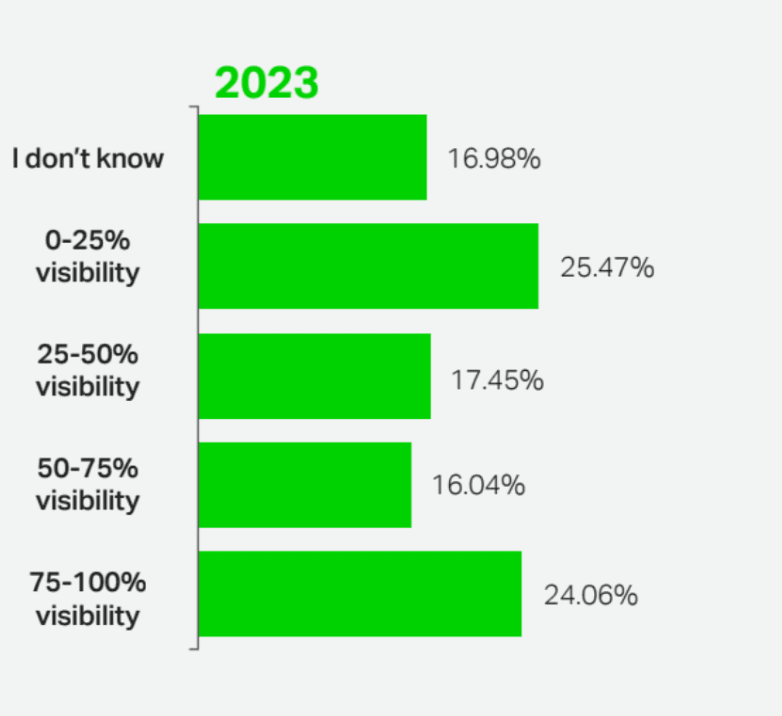

In our recent State of Specification Management Survey, when respondents were asked about the level of visibility into their specifications 43% of respondents had 0-50% with an additional 17% who didn’t know their levels of visibility at all.

With this lack of visibility, teams can’t search or consolidate specification data easily, forcing teams to turn to manual processes to search for data. When static processes and legacy systems dominate company data, not only is visibility decreased but businesses face many other risk factors.

Taylor Farms, an American-based producer of fresh-cut fruits and vegetables, has faced similar issues stemming from legacy systems in place.

Like Ocean Mist, Taylor Farms is challenged with SKU and product proliferation. The use of shared Excel files, paper workflows, and phone calls to communicate this critical product specification information was both manual and time-consuming – opening the business up to risk.

Creating Integrated Data Streams and United Teams

In an effort to find a solution, companies like Ocean Mist and Taylor Farms chose to implement Specright to not only meet current company needs but also allow team members to expand and act on the goals of other departments.

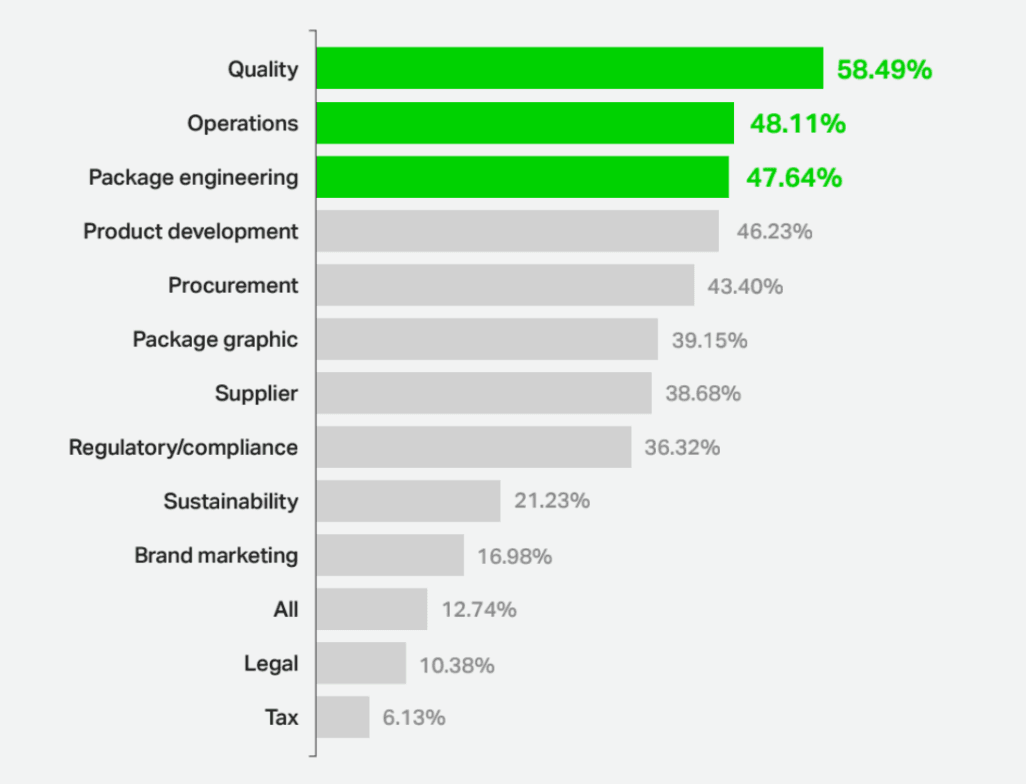

As seen in Figure 2, below now more than ever departments across companies are relying on specification data for business operations and success.

With increased supply chain complexity and more product variation, companies are recognizing the value of Specright when it comes to team collaboration and ensuring that all departments have access to specification data.

Webinar: State of Specification Management

If you haven’t had a chance yet, please register for the State of Specification Management Webinar. I’ll be joined by Laura Berlanga from Ocean Mist Farms, John Blake, Sr. Director Analyst, at Gartner, and Laura Foti to discuss more of the survey findings, share best practices, and showcase the power of a spec-first approach.

Explore More Blogs

Get Started

With Specright’s Solution Suite, you can digitize, centralize, and link your specification data to drive efficiencies, intelligence, traceability, and collaboration within your organization and across your supply chain network.