Quality Management

Streamline quality processes to resolve issues faster

Manage every quality process in one place, from incident intake to reporting, with built-in automation and dashboards.

Why Specright for Quality Management

Centralize Quality Data

Manage incidents, audits, and corrective actions in one system for full traceability.

Resolve Issues Faster

Automate quality workflows and approvals to speed incident resolution.

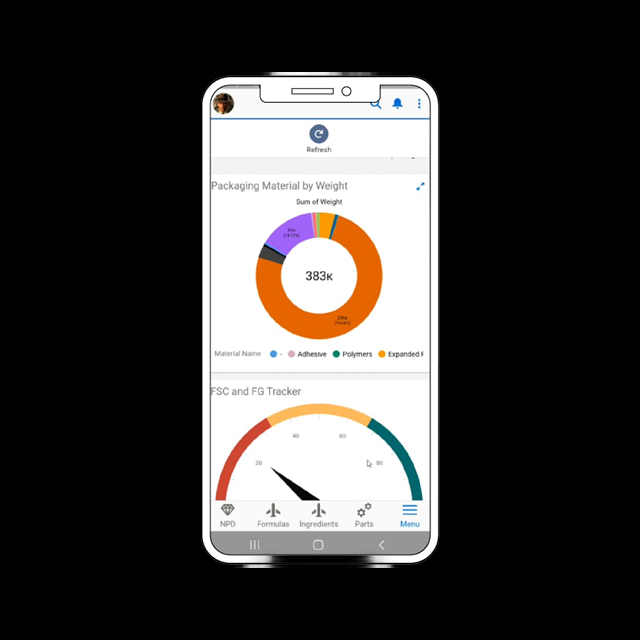

Monitor Quality Trends

Track issues and supplier performance with real-time dashboards and reports.

Trusted by Fortune 500, private label retail & challenger brands

Key Features

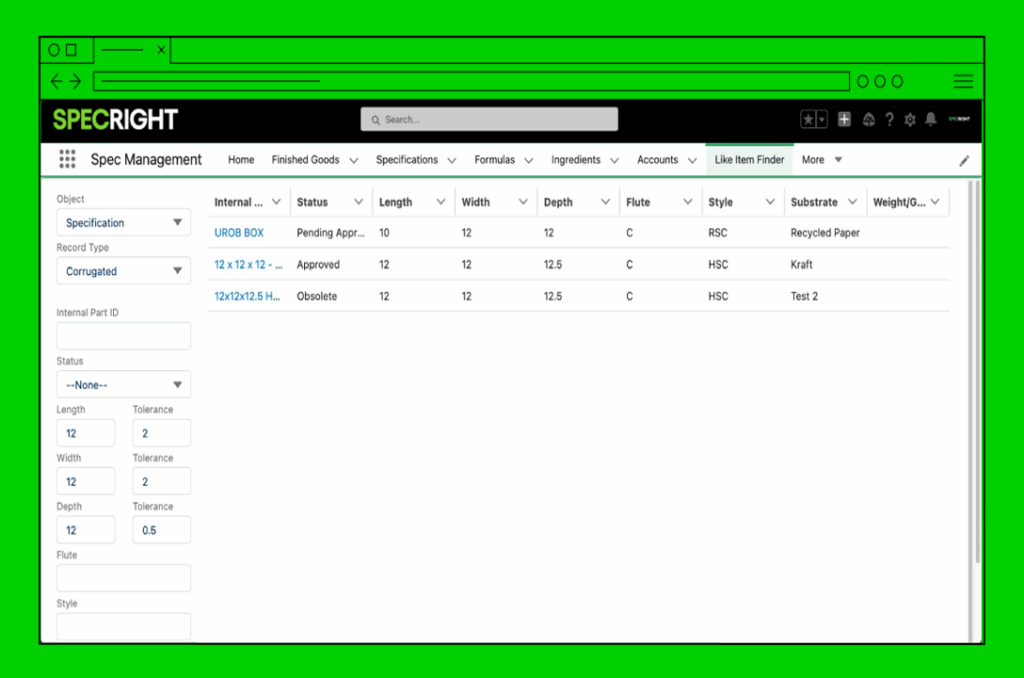

SCAR, CAR, Non-Conformance

Quickly create and link actions to the right spec or product to identify, correct, and prevent issues.

COA Management

Manage Certificates of Analysis in one place to easily verify incoming materials meet standards.

Test Results & Attributes

Set requirements, capture results, and trace at the lot level to ensure products meet specs.

Impact Metrics

30%

Reduced Risk of Recalls

15%

Faster Return of Market for Recalled Products

40%

Fewer Rejected Shipments

30%

Faster Preparation of Regulatory Audits

What Product Experts Say

“I no longer have to search

for information and validate the source—I grab

the information I need from Specright and

move on with my project.”

Laura Berlanga

Product Innovation & Research Manager, Ocean Mist Farms

“Being able to review specs

with sales data is changing

the way we do business.”

Molly Fiedler

Chief Innovation Officer, Kira Labs

“Having more people access data

allows us to put world class operating procedures in place.”

Kris Corbin

Chief Supply Chain Officer, Bright Future Foods

How to Use Data to Prevent Quality Issues in Your Supply Chain eBook

Recalls, incorrect orders, and product waste all stem from one fundamental problem: the way businesses are approaching quality management.

Discover the Impact

If you get the spec right,

the rest follows

With digitized, shareable specs, you can ensure your teams and suppliers are on the same page– at all times.