What is Specification Data Management™ (SDM)?

Specification Data Management (SDM™) software is a specialized data management system that templatizes and standardizes specs across the supply chain, enabling collaboration, accuracy, and improving time-to-market. Specification data captures data elements items such as raw materials, ingredients, formulas, packaging, finished goods, bills of materials (BOMs), quality control documents, and more.

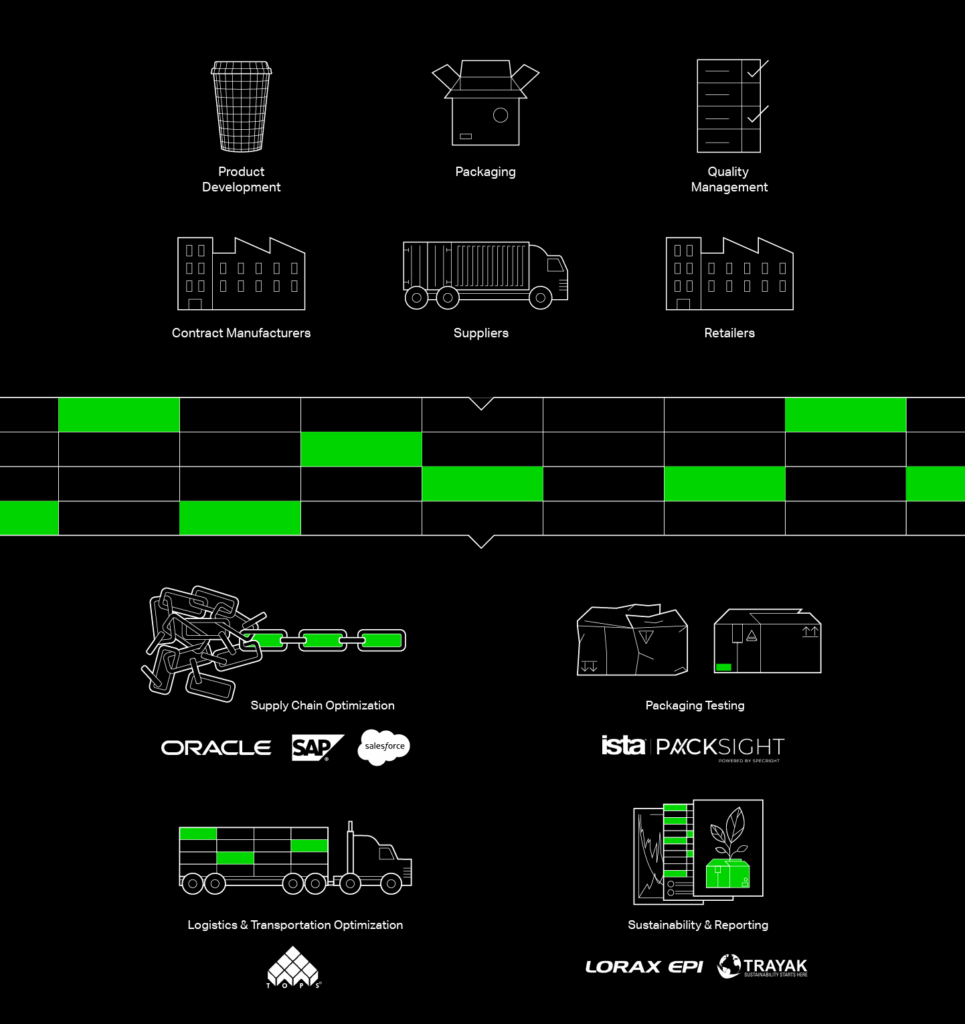

Specification Data Management Drives Downstream Systems

SDM is the foundation for supply chain systems, serving as the core data specification platform that ensures consistency and accuracy across all downstream applications. When companies implement SDM, downstream systems downstream become smarter and more accurate. As a cloud-based SaaS platform, it’s easy to pass data, metadata, and other critical information to other systems, making your SDM platform the ideal single source of truth for all stakeholders.

How does SDM differ from systems like Product Lifecycle Management (PLMs), ERPs (Enterprise Resource Planning), and data visualization tools? ERPs are financial systems, PLMs are used to build complex products like jet engines, and visualization tools are designed to aggregate data, not structure it. These systems were not built to structure, manage, and share data at the specification level. Unlike legacy systems of yesterday, SDM platforms can easily intake data from ERPs, PLMs, and data visualization tools, streamlining outcomes like cost optimization, faster product development, and advanced analytics.

SDM Enables Companies to Answer Key Business Questions

How can we reduce packaging costs across product lines?

How can we make products more sustainable and measure progress?

How can we ensure compliance with new regulatory requirements?

How can we increase speed-to-market for new products?

How can we consolidate SKUs across our portfolio?

How can we reduce packaging costs across product lines?

Why Food & Bev Companies Use Specright

Break down data silos across your organization to:

- Accelerate Speed to Market: Consumers demand product variety. With Specright, keeping track of specs in one place helps you go faster.

- Ensure Food Safety & Quality: Recalls often occur due to a lack of accurate data and ability to track changes. With Specright, ensure the spec is right every time.

- Streamline Reporting & Compliance: Whether it’s sustainability reporting or FSMA compliance, managing your products at the spec-level allows for easy and accurate reporting.

Specification Management Adoption Guide

With many companies still using spreadsheets, emails, and shared drive to manage specification data, the need for a purpose-built Specification Management system, including open source options, is increasingly becoming more crucial to meet today’s demands and scale operations.

By connecting specifications to other critical data such as suppliers and facilities, organizations can create a digital thread using Specright as their supply chain platform.

Everything You Need in One Platform

Packaging Management

Our digital, searchable platform puts data at your fingertips – and keeps your packaging teams on the same page.

Product Data Management

Accelerate time to market with clean, up-to-date product data shared across teams and suppliers.

Supplier Collaboration

Bring suppliers into your spec-first PLM for faster collaboration with accurate, up-to-date specs and shared workflows.

New Product Development

Centralize specs, projects, and suppliers to accelerate speed-to-market.

Manufacturing Instructions

Link formulas, lines, processes, and process steps for clear, consistent execution.

Formulation, Labeling & Claims

Create and optimize formulas in one place, from concept to claims, with AI-driven automation and insights.

Artificial Intelligence

AI that actually works—because it’s built on accurate, spec-level data connected across the entire lifecycle.

Learn More About Matthew’s Story and the rise of Spec Management in his book “The Evolution of Products and Packaging”

Available for download here or for purchase on Amazon.com